Description

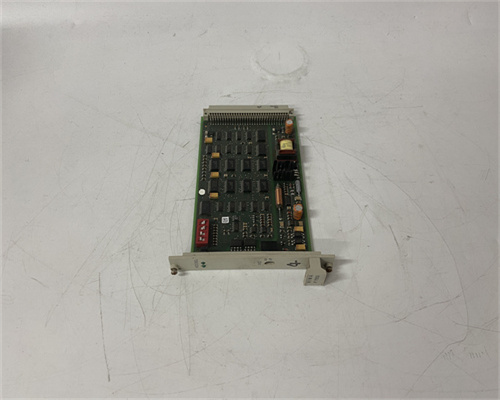

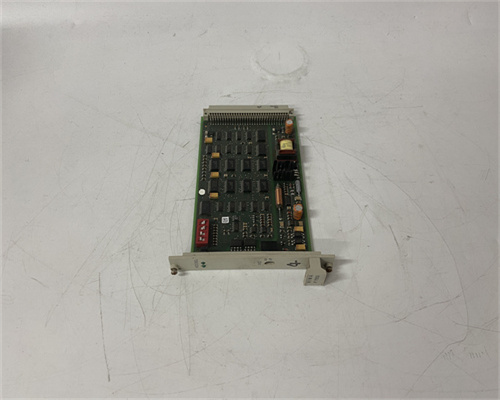

HIMA F7553 Production Description

Based on information found online and what we know about similar HIMA products, here’s a possible production description for the HIMA F7553:

Function:

The HIMA F7553 is a coupling module used within the HIMax safety system. It likely acts as an interface between:

- An I/O subrack containing input/output (I/O) modules for connecting sensors and actuators.

- A central processing unit (CPU) module within the HIMax system responsible for safety control logic.

The F7553 facilitates data exchange and signal transmission between these components, ensuring safe operation of the connected equipment.

Possible Production Process:

-

Component Sourcing: HIMA likely sources various electronic components for the F7553:

- Integrated circuits (ICs) for handling data communication and signal processing.

- Optocouplers or isolation transformers to provide electrical isolation between the I/O subrack and the CPU module, enhancing safety.

- Communication interface components (if applicable) depending on the specific data transmission protocol used within HIMax.

- Passive components like resistors and capacitors for signal conditioning and circuit stability.

- Housing components for mechanical protection and mounting on a DIN rail or similar mounting system.

-

Printed Circuit Board (PCB) Manufacturing: The PCB design is likely created using computer-aided design (CAD) software. The PCB itself is fabricated according to the design, potentially involving multiple layers with etched circuitry and drilled holes for precise component placement.

-

PCB Assembly: Automated pick-and-place machines populate the PCBs with the procured electronic components. These components are then securely soldered onto the PCBs using reflow ovens or wave soldering techniques.

-

Testing and Quality Control: The assembled PCB undergoes rigorous testing to ensure proper functionality of all components and circuits. This may involve automated test equipment for comprehensive electrical checks.

- Communication protocols might be tested to verify reliable data exchange between the F7553 and connected modules.

- Electrical isolation tests are likely conducted to ensure the effectiveness of isolation measures.

-

Packaging and Shipping: Once all tests are passed, the F7553 is labeled according to regulations and securely packaged for shipment to distributors or end users.

Materials and Manufacturing Technology:

- High-quality electronic components to ensure reliable operation and long service life in potentially demanding industrial environments.

- Lead-free soldering processes complying with environmental regulations.

- Surface-mount technology (SMT) for efficient and compact PCB assembly (if applicable).

- Automated testing equipment for consistent quality control.

- Advanced isolation techniques to ensure safety within the HIMax system.

Finding More Specific Information:

Obtaining highly detailed information about the specific production process for the HIMA F7553 might be challenging. Here are some suggestions for further exploration:

- HIMA Website: Search the HIMA website for product manuals or data sheets related to the F7553 coupling module. These resources might provide details about its features, specifications, and compatibility with other HIMax components.

- Contact HIMA Directly: Reach out to HIMA’s customer support or relevant department. They might be able to share general information about the production process but may not disclose confidential details.

- Industry Resources: Search online for information about similar safety coupling modules used in industrial automation systems. Industry forums or technical websites might offer insights into typical production processes, but keep in mind the information might not be entirely specific to the HIMA F7553 model.

I hope this comprehensive description is helpful for understanding the possible production process for the HIMA F7553 coupling module!

All prices listed on the official website are subject to confirmation by contact: Wu Jiedong (manager).

Our product: brand new original packaging

Our warranty: All new or repaired parts have a 12 month warranty period beginning

Our payment: 100% telegraphic transfer of inventory items before shipment, conditions can be proposed!

If you have any downtime spare parts that you cannot find, please feel free to call or use email to contact me. If there are issues that the product cannot solve, please contact me. Product prices can be negotiated. Please do not consider contacting me!