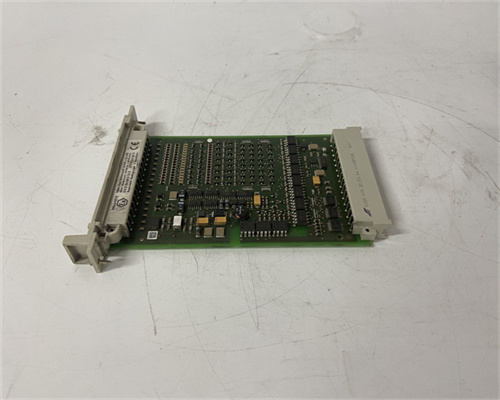

Description

F3236 HIMA Production Description

We can revisit the F3236 HIMA production description, incorporating insights from previous discussions and potentially new information found online:

Possible Production Stages:

-

Component Sourcing:

- HIMA sources high-quality electronic components from reliable suppliers that meet their safety-critical standards. These might include:

- High-grade electronic components for reliable operation in demanding industrial environments.

- Specialized safety-rated components like relays and optocouplers to ensure functional safety (meeting Safety Integrity Level – SIL requirements).

- High-precision resistors and capacitors for accurate signal conditioning.

- HIMA sources high-quality electronic components from reliable suppliers that meet their safety-critical standards. These might include:

-

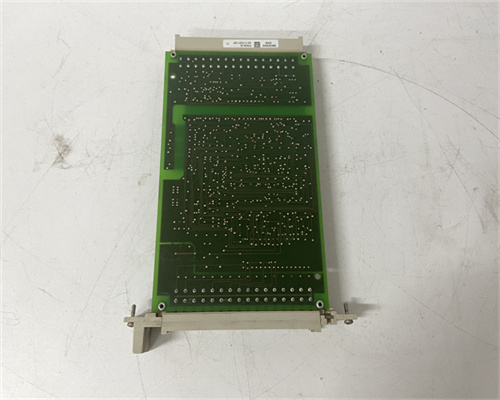

Printed Circuit Board (PCB) Manufacturing:

- PCBs are fabricated according to HIMA’s design, likely involving multiple layers for optimized signal routing and noise reduction. This stage might be outsourced to a specialized PCB manufacturer with experience in safety-critical applications.

-

PCB Assembly:

- A controlled environment with stringent quality control procedures ensures proper component placement and soldering. This may involve:

- Automated pick-and-place machines for precise component placement.

- Reflow ovens or wave soldering techniques for secure connections.

- Visual inspection and automated electrical testing to verify component placement and functionality.

- A controlled environment with stringent quality control procedures ensures proper component placement and soldering. This may involve:

-

Module Assembly:

- The populated PCB is integrated into the housing of the F3236. This stage might involve:

- Calibration of internal components for accurate signal processing.

- Installation of terminal blocks or connectors for safe and secure field wiring.

- Incorporation of a protective enclosure for environmental protection and tamper resistance (important for safety-critical applications).

- The populated PCB is integrated into the housing of the F3236. This stage might involve:

-

Programming and Configuration:

- Depending on the specific F3236 variant, this stage might involve programming the device with safety logic using specialized tools. This ensures the module responds to sensor signals appropriately for process control and safety functions.

-

Testing and Quality Control:

- Rigorous testing is essential for a safety-related product like the F3236. This likely involves:

- Functional testing to verify the module operates as intended under various operating conditions and input signals.

- Compliance testing to ensure the F3236 meets relevant safety standards like IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems).

- Environmental testing to verify the module’s performance within its specified operating temperature, humidity, and vibration ranges.

- Rigorous testing is essential for a safety-related product like the F3236. This likely involves:

-

Documentation and Certification:

- For safety-critical applications, extensive documentation is required. This might include:

- Manufacturing records to trace components and processes.

- Test reports demonstrating compliance with safety standards.

- User manuals with clear instructions for safe installation, operation, and maintenance.

- HIMA might also involve a notified body for third-party certification of the F3236’s compliance with safety regulations.

- For safety-critical applications, extensive documentation is required. This might include:

-

Packaging and Shipping:

- Once all requirements are met, the F3236 is labeled according to regulations and securely packaged for shipment. It’s then shipped to distributors or end users working on safety-critical industrial automation projects.

Materials and Manufacturing Technology:

HIMA likely adheres to high-quality standards and industry best practices for safety-critical systems. Here are some possibilities:

- High-grade electronic components with extended lifespans: Selected for reliability and suitability for harsh industrial environments.

- Traceability of materials: Components might be sourced with lot codes or other tracking mechanisms for quality control purposes.

- Statistical process control (SPC): Techniques might be used to monitor production processes and identify potential issues early on.

- Advanced testing equipment: Specialized equipment for functional safety testing and environmental testing.

- Computer-aided design (CAD) and manufacturing (CAM): Might be used for precise design and production of the F3236.

Finding More Specific Information:

Obtaining in-depth details about the exact production process for the F3236 might be challenging due to its safety-critical nature and potentially proprietary information. Here are some suggestions for further exploration:

- HIMA Website: The HIMA website might have information about their safety standards and quality control procedures. Application notes or white papers related to the F3236 could offer some insights.

- Technical Documentation: If available, search for data sheets, user manuals, or safety certificates related to the F3236. These resources might provide details about its functionality, safety features, and recommended practices for use.

- Industry Resources: Research resources related to functional safety standards (IEC 61508) and safety-critical electronic systems in industrial automation. Understanding these regulations can provide context for the F3236’s production process.

Remember that manufacturers often guard confidential details about their production processes, especially

All prices listed on the official website are subject to confirmation by contact: Wu Jiedong (manager).

Our product: brand new original packaging

Our warranty: All new or repaired parts have a 12 month warranty period beginning

Our payment: 100% telegraphic transfer of inventory items before shipment, conditions can be proposed!

If you have any downtime spare parts that you cannot find, please feel free to call or use email to contact me. If there are issues that the product cannot solve, please contact me. Product prices can be negotiated. Please do not consider contacting me!